Robomilkbar™ milk processing line

We release this fully equipped milk processing line - Robomilkbar dairy - from our showroom in Prague 9, Kolbenova.

It's got really max. 200 working hours in milk production, and some hundred hours of simulation with water only.

For new customers in Europe, we offer - free of charge - a training (max. 5 business days) course and personal take over of the technology in our showroom.

Product Specifications

PASTEURISATION | raw milk inlet 4°C/past. 72°~95°C (adjustable)-20 sec. holding time/past. milk outlet 4~40°C (adjustable) (depends on the tap water temperature)

TYPE OF PASTEURISER | Continuous flow pasteuriser (HTST), max. 600l per hour

POWER SUPPLY | 380V/3PH-50HZ

ABSORBED POWER | 45 kW (min. req. 80A) for the whole line

PRODUCT TYPES | Whole pasteurised milk, various cultured milk products (stirred)

PRODUCT PACKAGINGS | 95mm cups, Bottles (semi-automatic)

MATERIAL | Stainless Steel AISI 304 high polished

CONTROLLER | PLC with 5,7" Touch resistive HMI Panel (record of pasteurisation temperatures on a flash disc)

ICE WATER SYSTEM | Included. Ice water tank, DWM Copeland condensing unit

LIQUID RING PUMP | Included. Sanitary centrifugal pump 3000l/h to feed the pasteuriser with raw milk

RAW MILK TANK | Included. 1000l Raw milk receiver cooling tank with DWM Copeland condensing unit.

FERMENTATION TANK | Included. 2 X 250L Fermentation tanks automatically controlled from the main panel.

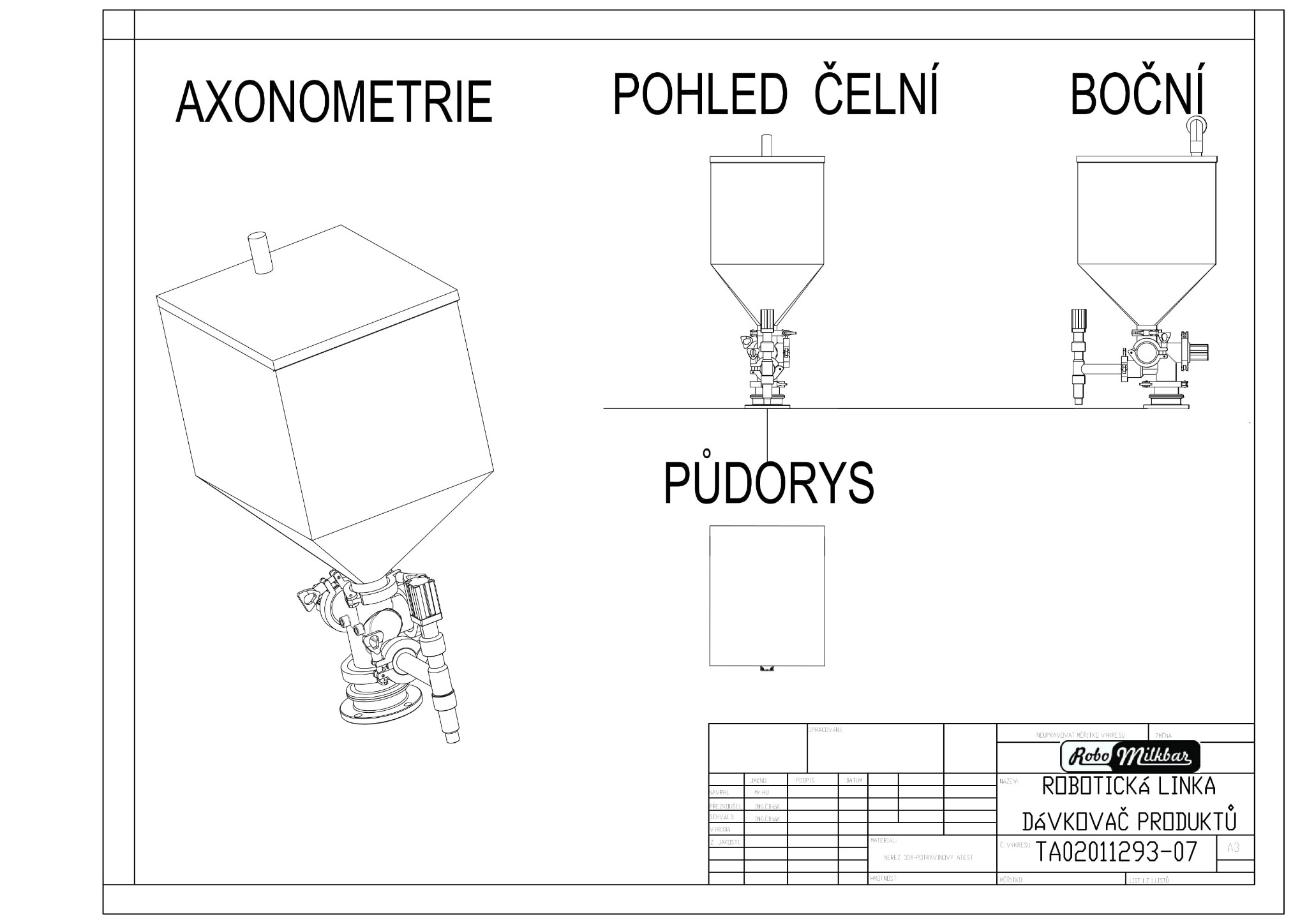

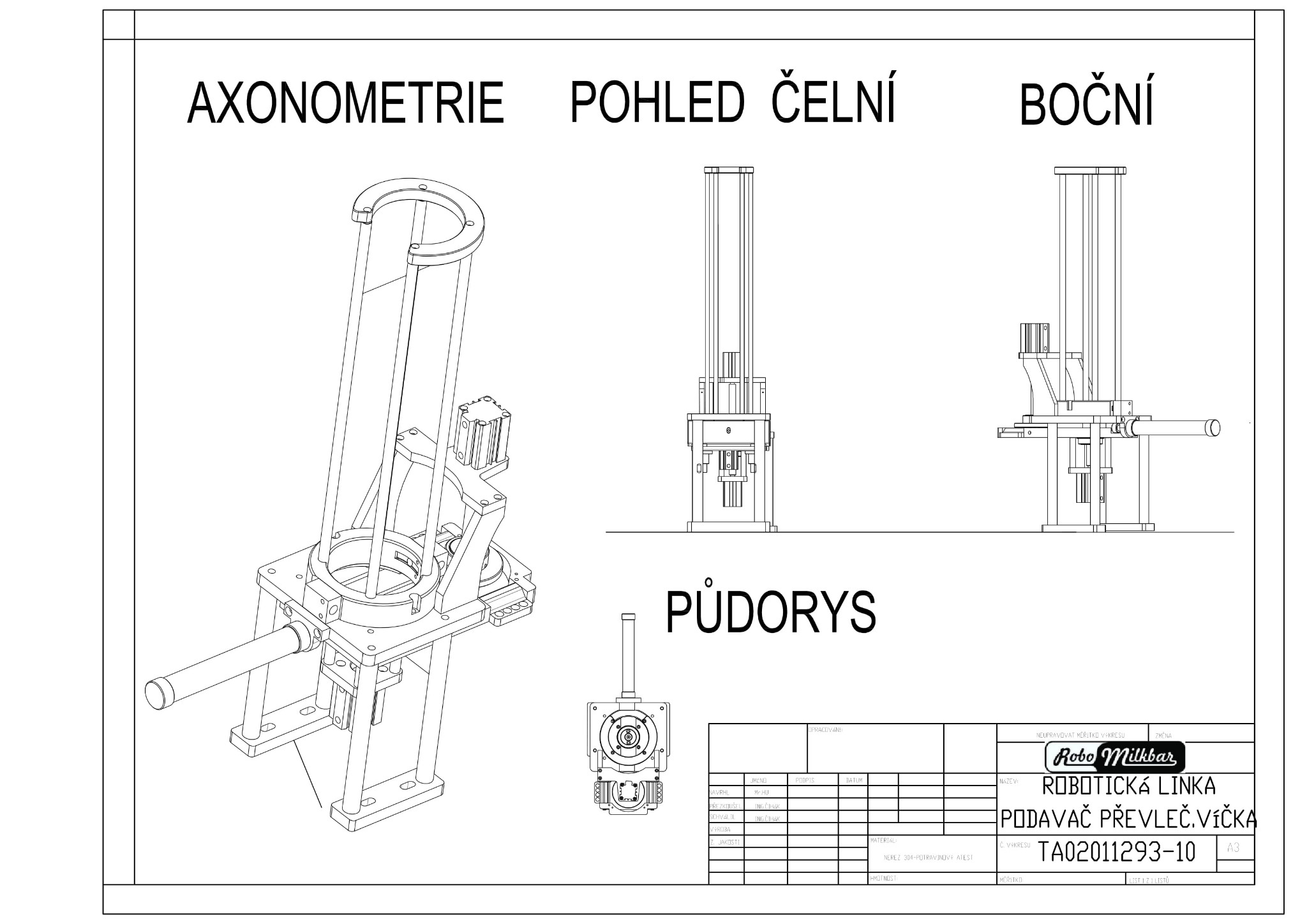

PACKAGING | Included. Semi automatic packaging line (1-3 workers per shift) designed for packaging of 95mm cups with 4 x 95mm Cup dispensing stations; 6 x Semi automatic filling stations with 20L hopper; 1 x 95mm Alu (heat-sealable) lid dispensing station; 1 x 95mm Alu (heat-sealable) lid press&sealing station; 1 х 95mm Plastic topping lid dispensing station; 1 x semi automatic cup box dispensing station; 1 x belt conveyor for finished cups in (or not in) boxes.

COLD ROOM | Included. Dismounted PUR panel walls + cold room insulated door + compressor and condensing unit to keep temperature at 3°C in max. 50 m2 space.

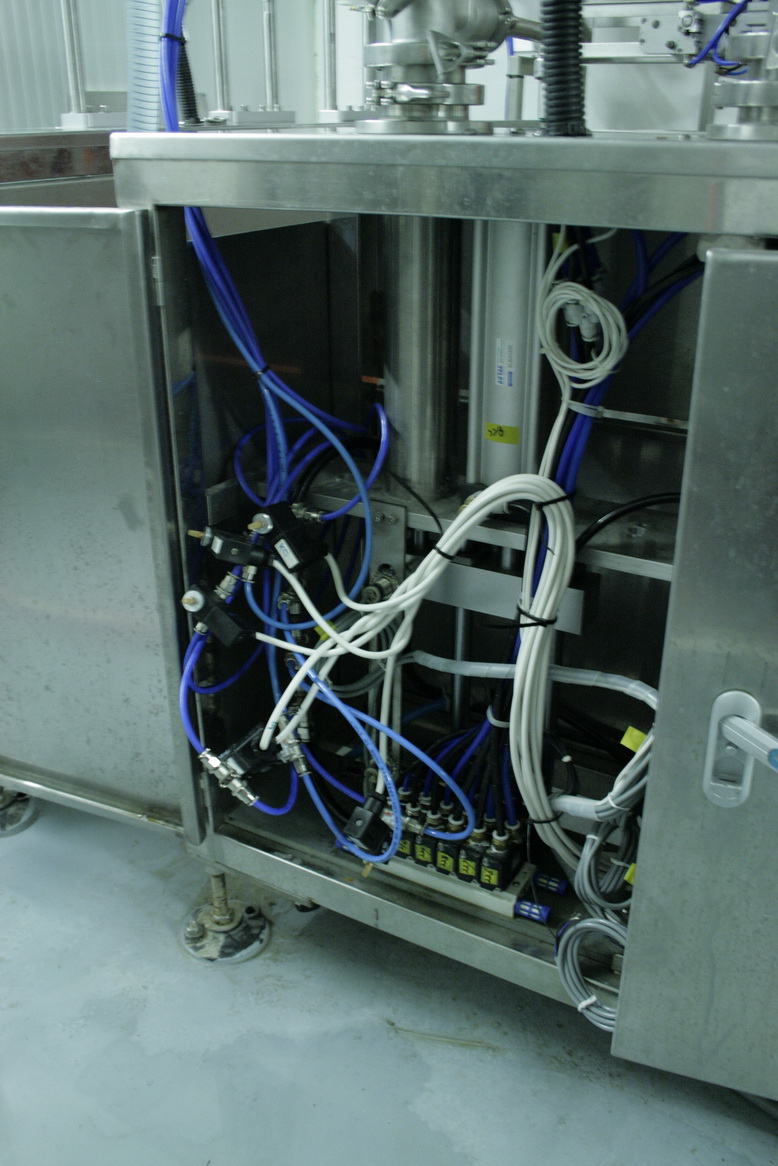

AUTOMATION | BR Automation PLC controllers for the whole line. Penumatic control valves almost in the whole system.

INTERNET REMOTE ACCESS | Yes. Tele2 Machine2machine worldwide 12 months package included.

MILK/CIP PIPES | Sanitary Stainless AISI 304 pipe Ø25 mm (customised length max. 5000 mm)

COMPRESSED AIR SYSTEM| Included. Sufficient air compressor, compressed air pipes/hoses for all the equipment, air filters, air freezer, air tank 500L.

TERMS&CONDITIONS| The equipment is being sold as is. If you are interested, you can contact us to arrange a meeting where you can inspect the equipment before the actual purchase. The price is ex works, but includes deinstallation and packaging of the equipment.

No warranty is provided.

We can quote our installation team to install & start up the technology in a new place. You will need to have your space ready for embedding of the equipment. Our hour rate is 30 USD per hour. For the installation we'll send 3 technicians with estimated time of installation max. 15 days. Technicians usually work 9-10 hours per day incl. lunch time.Food&accommodatin&travel cost is individually quoted.

We can also quote a shipping cost to any destination.

Our terms are 100% before expedition preferrably by T/T (wire transfer), paypal or cash.

Feel free to contact us anytime at info@milkbot.cz or call +420602175527